Case Sharing 1

MLP multi-layer packaging solution innovatively saves 25% of packaging materials

MLP (Multi-Layer Packaging) is an innovative packaging solution for all kinds of sliced foods, such as cheese, sausage, ham slices, etc. Compared with traditional independent packaging, MLP uses three layers of film to package two packages of products. Consumers can tear open the packaging layer by layer without affecting the preservation effect of the remaining layers of packaging, and the multi-layer structure saves one piece of film material for every two packages of products, saving 25% of the packaging material cost.

MLP case after printing

Solution features:

Good preservation: Applicable to modified atmosphere packaging and vacuum packaging processes to ensure food preservation

Open layer by layer: Consumers can open a single compartment separately without affecting the sealing of the remaining layers of packaging

Cost saving: Compared with the traditional continuous packaging solution, it can reduce the packaging material cost by 25%

Environmentally friendly: Reduce packaging plastics, reduce transportation energy consumption, and comply with environmental protection concepts

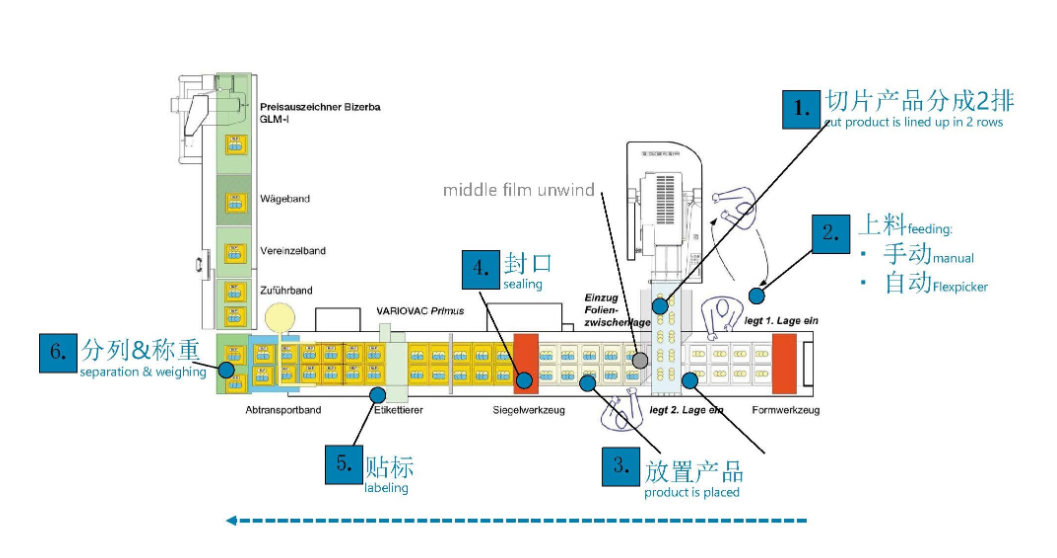

There is no need to design the machine from scratch to produce MLP packaging products. The good sealing and gas conditioning performance of VARIOVAC Primus allows it to support the sealing of three-layer packaging films after only adjusting the flow line part, making the MLP solution successfully implemented. Germany's second largest food retailer Rewe, the low-cost supermarket chain ALDI, and the Belgian Delhaize Retail Group have chosen VARIOVAC Primus equipment models to process MLP packaging to help them save packaging material costs.

VARIOVAC Primus在Rewe案例中的MLP方案布局

Case Sharing 2

Helping Cargill quickly respond to the demand for three-pack poultry meat packaging

In 2020, the meat purchasing department of Sam's Club China wanted to make a three-pack poultry meat product with a single package of 400 grams, which not only met Sam's commodity principle of large-scale single products, but also facilitated consumers to eat in small batches. However, there were few meat suppliers who could supply this packaging specification product in large quantities at that time.

Cargill China hopes to meet Sam's retail needs by updating packaging equipment.

Jiaji's Innovation Application Center

At Jiaji's Innovation Application Center, when watching the equipment display of VARIOVAC high-speed machine, Steven, the head of Cargill R&D, got the solution he wanted. "Steven, our German VARIOVAC equipment can pack samples for you." After communicating the needs, Alan, the head of Jiaji, responded quickly.

The samples were quickly sent to Sam's Purchasing Department. When the three-pack prepared poultry samples with flavors such as "New Orleans Chicken Wings", "Peppercorn Chicken", and "Japanese Teriyaki Chicken" were placed in front of Sam's purchasing staff, the product quality was highly affirmed by the other party: "Yes! This is the packaging, put it on the shelves immediately!" Therefore, the VARIOVAC online thermoforming equipment originally in the exhibition hall of Jiaji Innovation Center came to Cargill Chuzhou Factory and started production, and the three-pack poultry products soon became Sam's hot-selling products.

The good performance of the new product put the issue of production capacity before Cargill. "Can you give us an equipment solution with a production capacity of 2.5 tons per hour?" At this time, during the epidemic, Jiaji overcame difficulties and communicated with Cargill's technical department and Germany's VARIOVAC to determine the technical solution. Jiaji's after-sales staff solved specific problems on the production line during the epidemic and responded quickly to various problems encountered by Cargill.

VARIOVAC Primus

In the end, Cargill did not choose the other two large multinational equipment suppliers, but decided to purchase two new VARIOVAC Primus high-speed line equipment from Jiaji to produce both fresh cuts and processed poultry.

Later, when asked why Cargill chose Jiaji instead of the other two large multinational companies, Cargill replied to Jiaji: "Jiaji provides fast response services; Jiaji has comprehensive and professional technical qualities from meat product needs, packaging applications to equipment solutions; the VARIOVAC equipment sold by Jiaji has a high sealing success rate and excellent molding, which makes our packaging very glossy and has a good texture. In addition, due to excellent molding, the thickness of the packaging material can be reduced to reduce costs."

Case Sharing 3

Smart Solution to Packaging Problems - Shrink Film

Food safety has always been the first priority in the packaging process. High-quality packaging solutions can not only ensure food safety and beauty, but also greatly enhance the role of extending the shelf life of food, allowing consumers to enjoy safer, more reliable and delicious food.

In actual production, due to the diversity of packaging equipment and packaging materials, as the output increases, various packaging problems such as broken and leaked packages are prone to occur. The following is how Jiaji solves packaging problems in actual work.

Find problems and respond quickly

Recently, a customer encountered a difficult problem of broken packages. After the packaged products entered the heat shrink tunnel, sealed openings and holes appeared, and the broken package rate was as high as 40-50%. The damaged products needed to be repackaged. The customer's daily output was 6,000-8,000, which reduced efficiency and increased huge losses. This was really a headache.

After the problem occurred, the customer quickly communicated with the supplier for a solution, and finally reduced the broken bag rate from 40-50% to 15-20% by replacing the sealing machine cutter. Due to the urgency of production, the customer temporarily accepted the broken bag situation. Cost control is the top priority of the company, and the loss problem still exists, so it is a problem that needs to be solved.

Analyze the problem and find out the cause

Jiaji has had a good cooperative relationship with this customer for many years. By chance, the customer expressed the need for our assistance. After receiving the problem description, the technical team responded quickly and rushed to the company's production site as soon as possible.

Through the analysis of packaging equipment, shrink film materials, and operating processes, it was found that the problem mainly focused on sealing temperature and sealing time, which caused the culprit of "poor sealing". At the same time, the material characteristics of the shrink film and the matching degree of the current equipment are also important factors leading to poor sealing.

Determine the solution and solve the problem

After the engineer found the problem, he communicated the technical details with the team in time and confirmed the solution. The loss problem was imminent, so we decided to temporarily lend the customer a sealing machine. In order not to delay the production of the workshop, the engineer waited for the production to end at 8 pm and installed the equipment overnight. After several days of production follow-up, the broken package rate was reduced from 15-20% to 0.1%, solving the customer's problem.

During the implementation of the plan, we provided technical guidance and support throughout the process to help the company's employees master the new operating procedures and equipment parameter adjustment methods. After a series of rectification measures, our professionalism and timeliness laid a solid foundation for the company's production operations and market expansion.

Case Sharing 4

Functional materials make it easy to open the bag just by hands

author:Kevin Sun

edit:Cassie Wang

Tianjin Ershang Yingbin Meat Food Co., Ltd. is a large-scale state-owned meat processing enterprise under the Tianjin Food Group. The company's "Welcome" brand and cooked meat products have been in existence for 65 years since 1953. It has won many honorary titles such as “Quality Products” from the State and Tianjin. Cooked meat products have a variety of low-temperature sausage products which are packaged with stretch film, but this series of products has been a difficult problem for many years, that is, the packaging couldn’t be tear. “It’s no exaggeration to say that we sell products with scissors to some customers and they use scissors to open bags.” A production manager once mentioned the fact that it likes a joke.

After understanding the pain points on the packaging of the company's products, we have specially developed the "easy to tear" packaging. Through the specially formulated high-resistance sealing layer, it not only ensures the barrier property of the material, but also guarantees the shelf life of the product. It remains good transparency and bright after pasteurization. When the upper and lower membranes are used together, the sealing performance is good, but the packaging can be opened with a little force.

"With such an upgrade, we have no worries about product sales. We don't have to worry about how customers open their bags. This special functional material solves one of our big problems."